Exploring the Diverse Benefits of Specialized Equipment for Career and Technical Schools

January 14, 2026

Salon Furniture That Elevates Your Brand

January 16, 2026I still remember walking into a clinic we were consulting at a few years ago. The practice owner, a brilliant veterinarian, looked exhausted—not from the patients, but from his facility. "I feel like I'm fighting my own building," he told me. He had opted for custom-built-in cabinets years ago. Now, when his practice had grown, he needed to expand his workstations. Which, for him, meant a full mini remodel.

This has always stuck with our team. They had one big question: How do we design cabinets that adapt to the clients' practices without stressing them out about the effort and cost of repeated remodeling? Growth is inevitable. The key is to predict the unavoidable.

When you are designing a veterinary clinic, you are often forecasting what your needs will be in five or ten years. Will you add a specialist? Will your tech team double? Will you need new diagnostic equipment that hasn't even been invented yet?

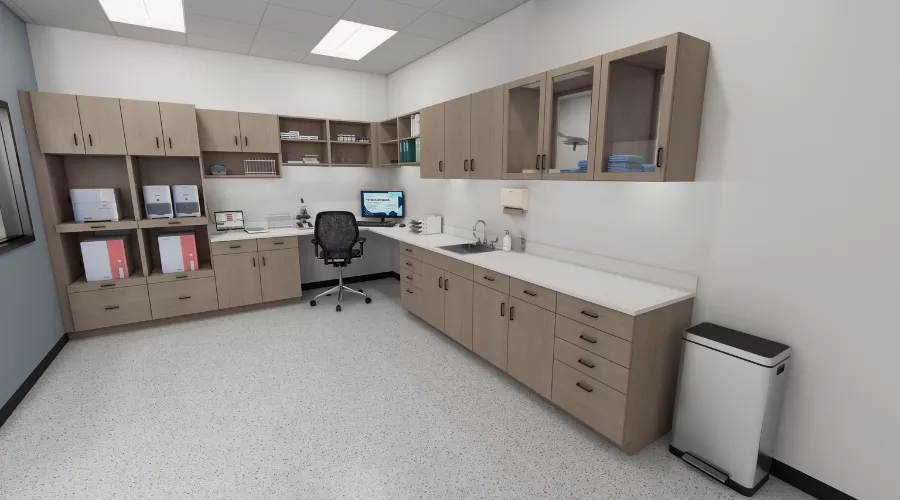

This is where modular casework changes the conversation. Unlike traditional millwork that is permanently glued and screwed into your drywall, modular systems are designed to adapt. At Kaemark, we’ve spent decades manufacturing solutions for high-traffic environments, and we’ve seen firsthand how modularity saves headaches, money, and time. Let’s dive into why this approach is becoming the standard for modern animal hospitals.

1. Flexibility That Future-Proofs Your Investment

Imagine buying a car that you could never take to a mechanic or upgrade. That is what you are doing with traditional fixed millwork. Once it is in, it is in.

On the contrary, modular veterinary cabinets are like building blocks. They appear built-in, but they are designed in a way that allows them to be moved, reconfigured, or expanded.

Adapting to Change

We recently partnered with an animal clinic, which began with a pharmacy area. Years later, they needed to expand their pharmacy. Because they used modular casework, we didn't have to demolish anything. We manufactured pieces that match the existing units, shifted them down, and installed new storage units in place. The clinic didn't close for a single day.

Flexibility like this is crucial because:

- Technology shifts: New analyzers or autoclaves might not fit your old counter depth. Modular systems can often be adjusted.

- Workflow changes: You might feel after six months that your prep station performs better on the left wall than on the right.

- Relocation: Suppose you decide to lease your space and move to a larger establishment, you can bring your cabinets with you. Thus, your furniture becomes your asset instead of being fixtures attached to the real estate.

2. Durability Built for the "Splash Zone."

Let's face it. A vet clinic is not your standard, quiet office; it’s a high-impact zone. We are talking about bodily fluids, claws, heavy equipment, and harsh chemical disinfectants used multiple times a day.

Residential-grade cabinets—and even some standard commercial millwork—are made with particle board cores that act like sponges. One spilled water bowl or a leaking pipe, and the cabinet swells, the laminate peels, and you have an ideal breeding ground for mold.

The Kaemark Difference

When we talk about modular casework for an animal hospital, we are talking about materials engineered for abuse.

- Steel vs. Wood: Many modular systems use metal sub-structures or high-density polymers that are impervious to water.

- Replaceable Components: This is my favorite feature. If a hyperactive Labrador chews the corner of a cabinet door, you don’t have to replace the whole cabinet. With modular systems, you can simply unclip the damaged door and replace it with a new one. It takes five minutes and costs a fraction of the cost of a complete repair.

3. Faster Installation and Less Downtime

If you have ever been through a renovation, you know the "dust phase." It gets everywhere. It delays opening. It stresses out the staff and the animals.

Traditional millwork is messy. Carpenters are on-site cutting wood, sanding, staining, and smelling up the place with adhesives. It can take weeks to finish an installation.

Plug and Play

With Kaemark’s veterinary cabinetry, your cabinets are entirely constructed offsite in our Texas manufacturing facility. So when it arrives at your clinic, it’s ready to install.

Speedy: Installation typically happens up to 75% faster than conventional millwork.

- Clean: There is very little dust and no harmful emissions created during off-site finishing, so there is no risk to nearby patients.

- Precision: Because the components are manufactured in a controlled environment, the fit and finish of the components are perfect every time. You will no longer need to deal with the frustration of crooked drawers due to a carpenter's insufficient skill set.

4. Financial Benefits and Depreciation

This is the part that usually makes the practice manager or the accountant smile.

Because traditional millwork is attached to the building, it is classified as real property. For tax purposes, it usually depreciates over 39 years. That is a long time to wait to write off an asset.

Modular veterinary cabinets are tangible items that are classified as personal property (furniture and equipment).

- Accelerated Depreciation: Typically, you can depreciate modular casework over a period of seven years.

- Tax Incentives: You may also be able to utilize Section 179, which provides you with a means for immediate write-off of the full cost of the object in the current tax year. (Always check with your CPA, but we see clients save significantly here).

When you are designing vet spaces, freeing up that cash flow allows you to invest in better medical equipment or marketing to grow your client base.

5. Designing for Efficiency and Flow

The best design considers not only the aesthetics of the furniture, but also how furniture can assist a team in doing their work.

Most traditional builds result in areas that are not used efficiently (i.e., "dead" spaces) and deep cabinetry that creates an area where supplies will be placed on shelves and forgotten. Modular engineering emphasizes ergonomics and utility. We often recommend specific modular setups that improve flow:

- Pass-throughs: Connecting surgery prep to the OR to minimize traffic.

- Glove and towel dispensers: Placed in upper cabinetry to eliminate clutter on countertops.

- Mobile carts: That match the stationary casework but can be wheeled to the exam table for a procedure and tucked away afterward.

By utilizing modular components, we can create a "cockpit" style environment where everything a technician needs is within arm's reach. Less walking means more time caring for patients.

Conclusion

When you plan to build a veterinary clinic, you need to follow a strategic approach that makes your space usable today and in the future. While cabinets are effective now, they may only be ideal for a short span. For this reason, working with a specialized animal clinic manufacturer allows you to prepare for today and the future without stressing over the natural growth of your practice. You deserve a space that works as hard as you do. At Kaemark, we build spaces that work.

If you are tired of fighting your facility or are just starting to dream up your new practice, we are here to help. At Kaemark, we combine deep manufacturing expertise with a genuine understanding of veterinary workflows.

Ready to future-proof your practice? Explore Kaemark's Veterinary Solutions or contact our team today to start the conversation.